Aftermarket Excavator Components: Comprehensive Testimonial and Contrast

Aftermarket Excavator Components: Comprehensive Testimonial and Contrast

Blog Article

How Aftermarket Excavator Parts Can Boost Your Construction Tools's Efficiency

In the world of building tools upkeep, the selection between original equipment supplier (OEM) components and aftermarket options can considerably influence the performance and performance of excavators. While OEM components are commonly acknowledged for their quality and compatibility, aftermarket excavator parts have been acquiring grip for their cost-effectiveness and prospective benefits.

Economical Alternatives for OEM Parts

When seeking affordable choices for OEM components in the construction tools market, it is important to carefully review the high quality and compatibility of aftermarket alternatives. While OEM parts are known for their exact fit and excellent quality, they commonly come with a costs cost. Aftermarket excavator components offer an even more affordable solution without jeopardizing on performance.

To make sure that aftermarket parts are an appropriate alternative, building equipment managers need to evaluate the online reputation of the aftermarket maker. Trustworthy aftermarket vendors generate parts that go beyond or fulfill OEM standards, providing a cost-effective choice without compromising top quality. Furthermore, compatibility with the particular make and version of the devices is important to avoid functional problems and potential safety threats.

Improved Performance and Efficiency

To make best use of functional performance and improve building tools abilities, buying aftermarket excavator components not just provides a cost-effective option but additionally adds to improved efficiency and productivity. Aftermarket components are developed to fulfill or surpass OEM specs, guaranteeing top quality and dependable efficiency. By replacing damaged or inefficient components with aftermarket choices, construction equipment can run at optimal levels, causing increased productivity on the job site.

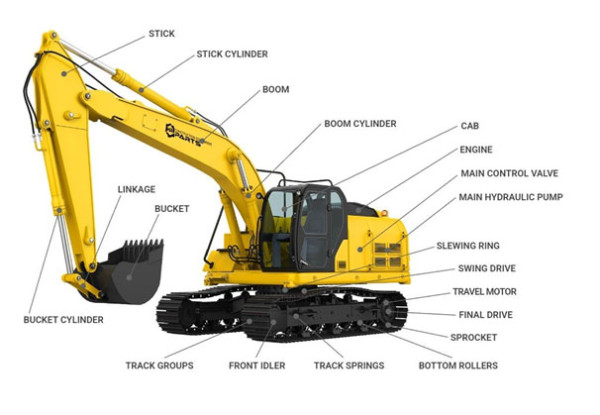

Better performance is a crucial benefit of making use of aftermarket excavator parts. These parts are usually engineered with sophisticated innovations and products, enhancing the general performance and functionality of the devices (aftermarket excavator parts). Whether it's updating hydraulic systems, pail teeth, tracks, or various other vital elements, aftermarket components can help improve the excavator's performance abilities, allowing for smoother procedures and faster cycle times

Additionally, the boosted productivity achieved via aftermarket excavator components translates to cost savings and improved project timelines. With equipment running much more effectively and successfully, building and construction companies can finish jobs quicker, tackle even more tasks, and inevitably raise their profits. By purchasing aftermarket components, construction equipment can reach its full potential, providing remarkable efficiency and driving total performance.

Extended Lifespan of Excavator Components

The longevity and durability of excavator elements can be significantly extended through the utilization of top quality aftermarket components. Purchasing aftermarket excavator components that are specifically designed to satisfy or exceed the efficiency of initial equipment supplier (OEM) parts can result in an extra resistant and durable construction devices fleet. Aftermarket parts are frequently engineered with innovative materials and making procedures that boost their sturdiness, making them a lot more immune to deterioration in requiring construction settings.

Boosted Tools Integrity and Toughness

By Learn More Here enhancing the integrity and resilience of building and construction devices, aftermarket excavator components that outperform OEM elements add to an extra durable fleet efficient in holding up against the roughness of requiring building and construction settings. Aftermarket components are commonly produced utilizing sophisticated innovations and premium materials, causing boosted devices durability and decreased downtime. These components are designed to surpass or meet OEM requirements, making certain a greater level of efficiency and integrity in the area.

The boosted dependability and toughness used by aftermarket excavator parts translate into price financial savings for building business. With decreased devices failures and the need for fewer fixings, businesses can operate much more effectively and maximize their productivity. Additionally, the improved resilience of these parts means that construction tools can withstand severe working problems without jeopardizing efficiency.

Enhancing Construction Jobs With Aftermarket Parts

Boosted construction task effectiveness can be attained through the critical integration of high-performance aftermarket excavator components. By utilizing aftermarket components that are especially developed to boost the performance of building tools, project supervisors can optimize different facets of their building tasks. These aftermarket components are engineered to improve the performance and performance of excavators, leading to smoother procedures and raised efficiency at work website.

One key benefit of integrating aftermarket excavator parts right into building jobs is the potential website here for faster completion times (aftermarket excavator parts). Updated components such as premium hydraulic cyndrical tubes, precision-engineered buckets, and sturdy undercarriage components can aid expedite tasks and improve processes. This effectiveness not just conserves time yet additionally reduces labor costs and reduces downtime, eventually adding to general job success

Final Thought

In conclusion, aftermarket excavator parts offer a cost-efficient option to OEM components while offering improved efficiency, productivity, and expanding the life expectancy of tools elements. By utilizing aftermarket components, building tools reliability and resilience can be boosted, resulting in optimized building and construction jobs. Consider including aftermarket components into your building and construction devices maintenance and repair work approaches to optimize efficiency and productivity on duty website.

In the world of building devices upkeep, the selection between original devices supplier (OEM) components and aftermarket options can significantly affect the performance and efficiency of excavators. While OEM parts are commonly acknowledged for their top quality and compatibility, aftermarket excavator components have actually been getting grip for their cost-effectiveness and possible advantages.To make sure that aftermarket components are an appropriate option, building devices managers need find out this here to evaluate the credibility of the aftermarket supplier.By improving the dependability and toughness of construction tools, aftermarket excavator components that outperform OEM elements add to a much more resilient fleet capable of withstanding the roughness of requiring building environments.In conclusion, aftermarket excavator components use an economical option to OEM parts while giving enhanced performance, productivity, and expanding the life expectancy of equipment parts.

Report this page